Feinguss

Als professioneller Hersteller von Feingussteilen wird unsere Spezialtechnik häufig angewendet, um schwerere, stärkere und komplexere Formen für Feingussteile zu erhalten. Wenn Sie mit uns handeln, erhalten Sie mehrere Vorteile wie niedrigere Kosten, einen günstigeren Formprozess für komplexe Designs und eine höhere Genauigkeit. Ein weiterer Wettbewerbsvorteil von Maple Machinery ist seine führende Position in China für Gießtechnologie. Wir bieten Präzisionsguss- und Verarbeitungsdienste auf Mikrometerebene an.

- View as

Hydrauliksystem Edelstahl-Gussteile

Die Edelstahl-Gussteile des Hydrauliksystems von Maple Machinery sind für ihre Zuverlässigkeit bekannt, aber unsere auf Zuverlässigkeit basierende Arbeitsmoral hört hier nicht auf. Wir möchten sicherstellen, dass dies in allen Aspekten unserer Arbeit zum Ausdruck kommt, von unseren Produkten bis hin zu Kundenservice und Partnerschaften. Wir sind stolz darauf, langfristige Kundenbeziehungen aufzubauen.

WeiterlesenAnfrage absendenMarine-Edelstahl-Gussteile

Maple machinery is a professional manufacturer located in Ningbo, China. More than 15 years of experience in the steel industry. Our products mainly include Marine Stainless Steel Casting Parts. Our products have been exported to many countries in Europe and America. We have a wealth of foundry experience, but also a number of stable Marine industry customers.产品内容 Product Introduction Maple machinery offers a wide range of custom Marine Stainless Steel Casting Parts. Stainless steel is resistant to corrosion and heat, has aesthetic appeal and low life cycle cost, is fully recyclable and has a good strength-to-weight ratio. We offer austenite, ferrite, martensite and biphase grades: we have hot or cold rolled and various surface treatments such as bright annealing. You can count on our experience. 2. Product Parameter (Specification) Item Marine Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Marine Maple machinery has been the most demanding supplier of Marine Stainless Steel Casting Parts for more than 15 years. Our reputation has earned us partners and valued customers who follow the most stringent requirements in terms of microstructure integrity, dimensional tolerances and quality control. Our products meet customers' requirements and standards. 4.Supporting Service for Marine As mentioned above, in order to work in adverse conditions, the performance of the Marine Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Marine Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Marine We have manufactured a wide range of Marine Stainless Steel Casting Parts. The following are typical products: Ground engaging tools: drill bits, carbide tipped tool, forged bucket tooth, auger.... 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.

WeiterlesenAnfrage absendenEdelstahl-Gussteile der Recyclingindustrie

Maple Machinery setzt die neueste Technologie in unserem Feingussverfahren ein, um qualitativ hochwertige Gussteile aus Edelstahl für die Recyclingindustrie kostengünstig und termingerecht herzustellen. Wir sind ständig auf der Suche nach neuen Technologien und innovativen Wegen, um unseren Feingussprozess für die Recyclingindustrie, unsere Effizienz und Qualität zu verbessern und unsere Vorlaufzeit zu verkürzen.

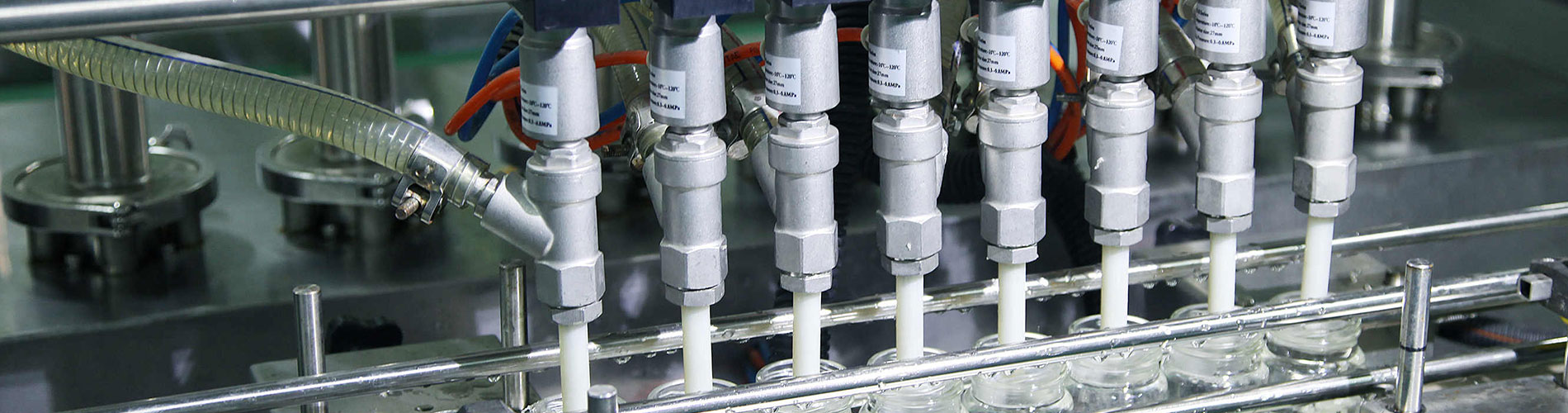

WeiterlesenAnfrage absendenEdelstahl-Gussteile für Lebensmittelverarbeitungsmaschinen

Für Food Process Machine fungieren die Maschineningenieure von Maple als verlängerter Arm Ihrer Organisation bei der Entwicklung von Präzisionsguss. Indem wir immer überlegen, ob es „technisch besser, anders, billiger und/oder einfacher“ gehen könnte, bekommen wir die beste Lösung zu einem konkurrenzfähigen Preis. Wir freuen uns, unser Wissen über Gießtechniken mit Ihnen zu teilen, um die besten Edelstahl-Gussteile für Lebensmittelverarbeitungsmaschinen zu entwickeln.

WeiterlesenAnfrage absendenVentilgussteile aus Edelstahl

Maple Machinery hat an der Herstellung von Edelstahl-Gussteilen für Ventile gearbeitet. Als führendes Unternehmen in den Bereichen Eisenbahn, Windindustrie, Offshore, Bau- und Industriemaschinen ist das Maschinenteam von Maple erfahren und dynamisch. Unsere Einstellung gegenüber unseren Kunden und unsere Hartnäckigkeit zur Weiterentwicklung gewährleisten exzellenten Service und Qualität

WeiterlesenAnfrage absendenSchwerindustrie-Edelstahl-Gussteile

Maple Machinery ist ein fortschrittlicher Hersteller von Gussteilen aus Edelstahl für die Schwerindustrie in China mit zufriedenen Kunden auf der ganzen Welt und einem etablierten Ruf in der Gießereiindustrie. Er verfügt über fast 20 Jahre Erfahrung in der Herstellung im Bereich Edelstahl. Insbesondere Maple Machinery ist in der Lage, anspruchsvolle Edelstahlgussprodukte anzubieten.

WeiterlesenAnfrage absenden